1.Umphumela wamanzi ohlelweni

I-Ice plug ku-valve yokwandisa, okuholela ekungabini kahle kwamanzi

II.Ingxenye yamafutha okugcoba ifakwe emulsified, yehlisa ukusebenza kokugcoba

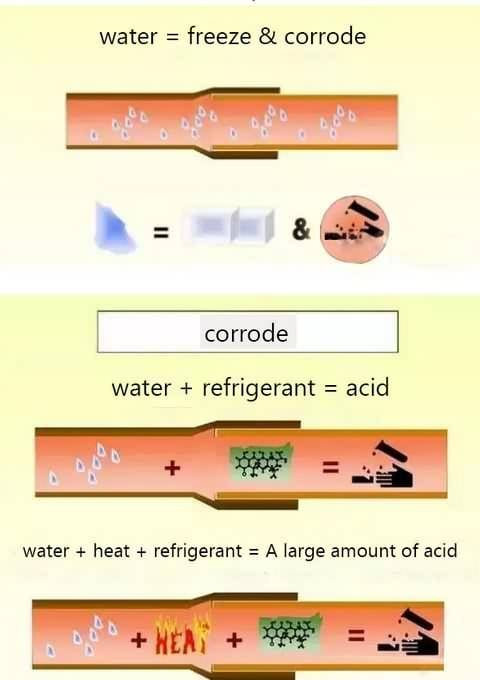

III.I-Hydrochloric acid ne-hydrogen fluoride kukhiqizwa ohlelweni lwesiqandisi, olungagqwalisa insimbi.Futhi inethonya elikhulu ku-valve plate, i-bearing and shaft seal.

IV.I-insulation kagesi yesiqandisi iyancipha.Ezimweni ezimbi kakhulu, i-compressor evalwe ngokugcwele izoshisa.

Indlela yokwelapha yokungena kwamanzi esistimu

Uma ukungenisa kwamanzi ohlelweni lokupholisa kungeyona into ebucayi, khona-ke shintsha isihlungi sokumisa izikhathi eziningana kuzolunga.Uma kunamanzi amaningi ohlelweni, sidinga ukusebenzisa i-nitrogen ukuze sikhiphe ukungcola ngezigaba, Faka esikhundleni isihlungi, uwoyela oyiqhwa, nesiqandisi , kuze kube yilapho umbala uphenduka ube luhlaza kusitholi sokubuka.

2.Umphumela wegesi engacondensable ohlelweni

Okubizwa ngokuthi i-non-condensable gas kubhekisela kulokho lapho usebenza ohlelweni lokupholisa, ekushiseni okukhethekile nokucindezela ku-condenser, igesi ayikwazi ukugoqa ibe yi-liquid, kodwa njalo ibe yisimo segesi.La magesi ikakhulukazi ahlanganisa i-nitrogen, umoya-mpilo, i-hydrogen, i-carbon dioxide, i-hydrocarbon gas, i-inert gas kanye nengxube yala magesi.

Igesi engancibiliki izokwandisa ukucindezela kokuqina, ikhulise izinga lokushisa lokukhipha umoya, inciphise umthamo wokupholisa futhi ikhulise ukusetshenziswa kwamandla.Ikakhulukazi uma i-ammonia isetshenziswa njengesiqandisi, igesi engajiki ngokuvamile izobangela ukuqhuma.

Indlela yokwelapha yohlelo inegesi engacondensable

Vala i-valve yokukhipha i-condenser bese uqala i-compressor, umpompa isiqandisi kusuka ohlelweni lokucindezela okuphansi kuya ku-condenser noma indawo yokugcina umfutho ophezulu.

Misa i-compressor bese uvala i-valve yokumunca.Vula i-valve ye-vent endaweni ephakeme kakhulu ye-condenser.

Izwa izinga lokushisa lomoya ngezandla zakho.Lapho kungekho umuzwa opholile noma ukushisa, ingxenye enkulu yokukhishwayo igesi engafinyeleli, ngaphandle kwalokho igesi yesiqandisi.

Hlola umehluko wezinga lokushisa phakathi kwezinga lokushisa le-saturation elihambisana nokucindezela kwesistimu yokucindezela okuphezulu kanye nezinga lokushisa lokukhipha le-condenser.

Uma umehluko wezinga lokushisa mkhulu, kubonisa ukuthi kunamagesi amaningi angacondensable, okufanele akhishwe ngezikhathi ezithile ngemva kokuba ingxube isipholile ngokugcwele.

I-3.Ithonya lefilimu yamafutha ohlelweni

Nakuba kukhona isihlukanisi samafutha ohlelweni lwesiqandisi, amafutha angazange ahlukaniswe azongena ohlelweni futhi ageleze nesiqandisi epayipini ukuze enze ukujikeleza kwamafutha.Uma ifilimu yamafutha ifakwe ebusweni bomshini wokushisa, i-condensation izinga lokushisa lizokhuphuka futhi izinga lokushisa lokuhwamuka lizokwehla, okuholela ekwandeni kokusetshenziswa kwamandla.Lapho ifilimu kawoyela engu-0.1mm ixhunywe ebusweni be-condenser, amandla okuqandisa we-compressor efriji yehla ngo-16% futhi ukusetshenziswa kukagesi kwanda. ngo-12.4%.Uma ifilimu kawoyela ingu-0.1 mm ngaphakathi kwe-evaporator, izinga lokushisa lokuhwamuka lizokwehla ngo-2.5 ℃, ukusetshenziswa kwamandla kuzonyuka ngo-11%.

Indlela yokwelapha yesistimu inefilimu yamafutha

Akuvamile ukubona inkinga kawoyela obuyayo ebangelwa ukwakheka okungalungile kwe-evaporator kanye nepayipi lokubuyisela igesi.Ngohlelo olunjalo, ukusetshenziswa kwesihlukanisi sikawoyela esisebenza kahle kunganciphisa kakhulu inani likawoyela elingena epayipini lesistimu.Uma ifilimu kawoyela isivele ikhona ohlelweni, singasebenzisa i-nitrogen ukuze sishaye kaningi kuze kube yilapho uwoyela oqandisiwe ongenankungu usuphelile. akhishwe.

Isikhathi sokuthumela: Dec-14-2018