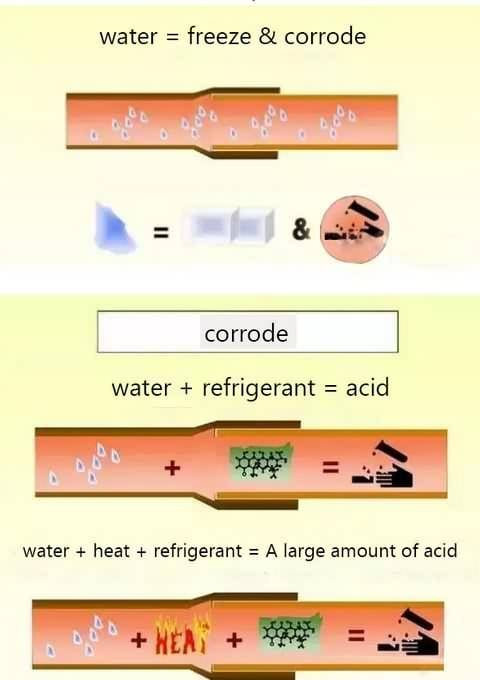

1.The effect of water on the system

I.Ice plug at expansion valve,resulting in poor fluid supply

II.Part of the lubricating oil is emulsified,reduce the lubrication performance

III.Hydrochloric acid and hydrogen fluoride are generated in the refrigerant system, which can corrode metal.And it has the greatest influence on valve plate, bearing and shaft seal.

IV.The electrical insulation of the refrigerant decreases.In serious cases, the fully enclosed compressor will burn down.

Treatment method of system water inflow

If the water intake in the cooling system is not serious, then change the drying filter several times will be fine.If there is a large amount of water into the system, we need use nitrogen to flush the pollution in sections, Replace the filter, the frozen oil, and the refrigerant , until the color turns green in the viewfinder.

2.The effect of non-condensable gas on the system

The so-called non-condensable gas refers to that when working in the cooling system, at the specific temperature and pressure in the condenser, the gas cannot be condensed into liquid, but always into a gas state. These gases mainly include nitrogen, oxygen, hydrogen, carbon dioxide, hydrocarbon gas, inert gas and the mixture of these gases.

The non-condensing gas will increase the condensing pressure, increase the exhaust temperature, reduce the cooling capacity and increase the power consumption. Especially when ammonia is used as the refrigerant, non-condensing gas will often cause explosion.

Treatment method of system has non – condensable gas

Close the condenser discharge valve and start the compressor,pump the refrigerant from the low pressure system to the condenser or high pressure reservoir.

Stop the compressor and close the suction valve. Open the vent valve at the highest point of the condenser.

Feel the air temperature with your hands.When there is no cool feeling or heat, the majority of the discharge is non-condensable gas, otherwise it is the refrigerant gas.

Check the temperature difference between the saturation temperature corresponding to the pressure of the high pressure system and the discharge temperature of the condenser.

If the temperature difference is large, it indicates that there are more non-condensable gases, which should be released intermittently after the mixture is fully cooled.

3.The influence of oil film on the system

Although there is an oil separator in the refrigeration system, the oil that has not been separated will enter the system and flow with the refrigerant in the pipe to form an oil circulation.If oil film is attached to the surface of heat exchanger, the condensation temperature will rise and the evaporation temperature will drop, resulting in the increase of energy consumption.When the oil film of 0.1mm was attached to the surface of the condenser, the refrigerating capacity of the refrigerating compressor decreased by 16% and the electricity consumption increased by 12.4%.When the oil film is 0.1 mm inside the evaporator ,evaporation temperature will drop by 2.5 ℃, power consumption will rise by 11%.

Treatment method of system has oil film

It is not uncommon to see a return oil problem caused by improper design of the evaporator and gas return pipe. For such system, the use of an efficient oil separator can greatly reduce the amount of oil entering the system pipeline.If the oil film is already present in the system, we can use nitrogen to flush several times until the non-foggy frozen oil is brought out.

Post time: Dec-14-2018